SERVICES

S

E

R

V

I

C

E

S

QUALITY CONTROL

ALEESCO recognize the importance of quality control, and have built up a Technical Department to provide full coverage of all quality aspects. The department is staffed by a qualified Engineer, who oversees all the testing for the Company. ALEESCO obtained ISO9001 certification many years ago, and strives towards continual improvement, through implementation of properly thought out and conceived procedures. Our central laboratory is equipped with all the necessary equipment to handle virtually all raw material tests, with highly trained laboratory personnel, to carry the tests out in accordance with the Company Inspection and Test Plan (ITP). This ensures that only high quality materials are used in the production of ready mixed concrete. Our satellite facilities have plant laboratories, equipped and staffed to carry out in process tests on the concrete prior to delivery to the customer, and can when required provide site technical staff to assist the contractor in monitoring the concrete on arrival at site. All testing is documented, so that a huge data base on all ALEESCO mix design performance is maintained

HOT WEATHER CONCRETING

To facilitate temperature requirements during hot weather, Aleesco batching plants are all equipped with water chillers, and our main depot has ice making plants, to deal with extreme temperatures. All ice is weighed and combined with the chilled water, to maintain the design w/c ratio of the concrete, ensuring that quality is not compromised

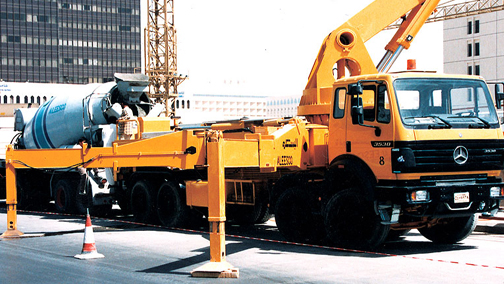

WORKSHOP

Aleesco has a fully equipped workshop, including turning machines and lathes, to provide a full maintenance and servicing program for our extensive fleet of vehicles, and fixed plant. Records of all servicing and repairs are maintained by the Workshop. The Workshop is managed by a qualified Engineer, and all maintenance staff are trained in their specialized discipline.

Document Controller

Educated and computer literate. Responsible for storage of all test reports, and for compiling all submissions. Based in the Central Laboratory Technical Office.

Senior Technician

Educated and experienced in concrete and raw material testing. Responsible for carrying out or overseeing the compressive testing, and materials testing. Also assists in all laboratory trial mixes. Based at the Central Laboratory.

Sample Receiver

Trained and experienced. Responsible for receiving all concrete test specimens, documenting them, stripping them from their moulds, curing them, and capping cylinders in preparation for testing. Monitors the curing conditions, to ensure samples are cured according to appropriate standards. Assists in laboratory trial mixes. Based at the Central Laboratory.

Cube Collector

Qualified light vehicle driver, responsible for collecting all concrete specimens from site, and all raw material samples from the batch plants. Also delivers test cylinder/cube moulds to the plants or sites, and transports technical staff where required. Based at the Central Laboratory.

Plant Technician

Trained and experienced. Responsible for monitoring the concrete production, taking slump and temperature readings, and making our own QC test samples. Also monitors and samples raw materials delivered to the plant, to be sent to the Central Laboratory. Based at the batching plant laboratory.

Site Technician

Trained and experienced. Responsible for carrying out the testing of concrete on site, taking slump and temperature readings, noting results and liaising with the appropriate Plant Technician, to ensure constant adherence to the specification requirements. Also makes cube/cylinder specimens where required for Contractor's QC needs.